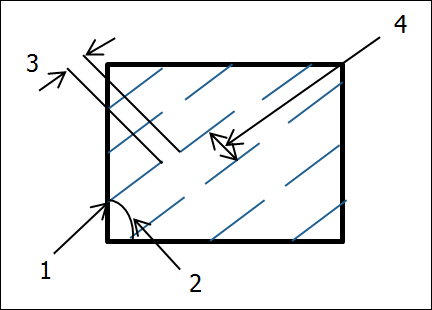

Line Patterns of Cross Section Components

Functions Introduced:

| |

| |

| |

| |

| |

| |

| |

| |

Creo Parametric supports hatch pattern files of the *.pat file format. The new hatch supports nonlinear hatching styles.

The old hatch uses the Xhatch *.xch file format. It is recommended to use the *.pat files. Refer to the Creo Parametric Online Help for more information.

The function ProXsecCompXhatchGet() returns the line patterns of a cross section component based on the specified cross section handle and the ID of the cross

section component. The line patterns obtained are ProXsecXhatch structures that contain the following fields:

| • | angle—Specifies the angle of the line patterns. |

| • | spacing—Specifies the distance between the line patterns. |

| • | offset—Specifies the offset of the first line in the pattern. |

Note

The functions ProXsecCompXhatchGet(), ProXsecCompXhatchAdd(), and ProXsecCompXhatchReplace() support only the old hatching styles, that is, the *.xch file format.

The function ProXsecCompXhatchAdd() adds a line pattern to a specified cross section component. This function takes the handle to the cross section, the ID of

the cross section component, the handle to the drawing view containing the cross section component and a pointer to the ProXsecXhatch object as its input arguments.

Note

If the cross section component already includes a line pattern, then the function ProXsecCompXhatchAdd() does not add a line pattern.

The function ProXsecCompXhatchReplace() replaces all existing line patterns of a specified cross section component with a new one.

The function ProXsecCompXhatchStyleGet() returns information about the style of hatch pattern in the specified cross section component. The output argument p_xhatch_style returns a ProXsecXhatchStyle handle. The structure ProXsecXhatchStyle contains the following information:

| • | type—Specifies the type of hatch. The valid values are:

|

| • | ProXsecXhatchPattern—Specifies a structure that contains information about the hatch pattern in a cross section. It contains the following information:

|

Note

The functions ProXsecCompXhatchGet() and ProXsecCompXhatchStyleSet() support only the old hatching styles, that is, the *.xch file format.

The function ProXsecCompXhatchStyleSet() sets the hatch pattern for the specified cross section component using the ProXsecXhatchStyle structure.

The function ProXsecCompNewXhatchStyleGet() returns information about the style of old and new, that is, nonlinear hatch pattern in the specified cross section component.

The output argument p_xhatch_style returns a ProXsecNewXhatchStyle handle. The structure ProXsecNewXhatchStyle contains the following information:

| • | type—Specifies the type of hatch. The valid values are:

|

| • | ProXsecXhatchPattern—Specifies a structure that contains information about the old hatch pattern in a cross section. It contains the following

information:

Note

When the cross section has old hatch patterns, the field *new_lines in the structure ProXsecNewXhatchStyle is returned as NULL.

|

| • | ProXsecNewXhatchPattern—Specifies a structure that contains information about the new hatch pattern in a cross section. It contains the following

information:

Note

When the cross section has new hatch patterns, the field *old_lines in the structure ProXsecNewXhatchStyle is returned as NULL.

|

The function ProXsecCompNewXhatchStyleSet() sets the hatch pattern for the specified cross section component using the ProXsecNewXhatchStyle structure.

Note

When you set new hatch patterns for the cross section, pass the field *old_lines as NULL in the structure ProXsecNewXhatchStyle. Similarly, when you set old hatch patterns for a cross section, pass the field *new_lines as NULL in the structure ProXsecNewXhatchStyle.

Use the function ProXsecCompNewXhatchStyleSetByName() to replace an existing hatch pattern with the specified hatch pattern. This function supports only new, that is, nonlinear

hatch patterns. For the replacing hatch pattern, you can also set the type and color attributes.